Small update:

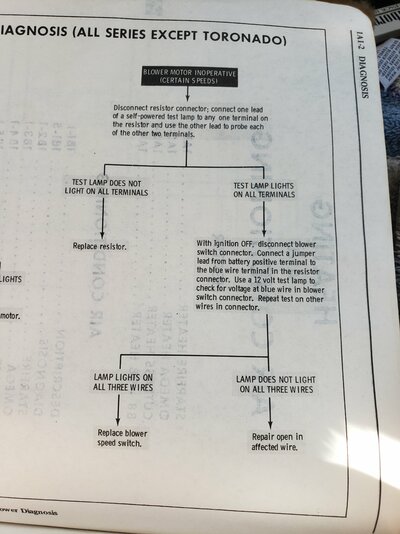

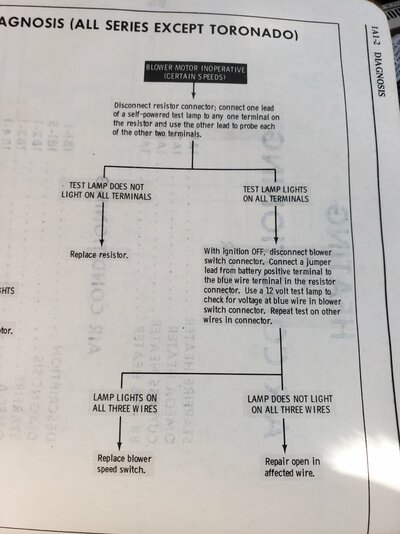

I took my voltmeter to the blower motor's positive electrical connector. The reading on the meter goes as follows:

Lowest: 5-7 volts

Second lowest: 12 volts

Second highest: 12 volts

Highest: Nothing

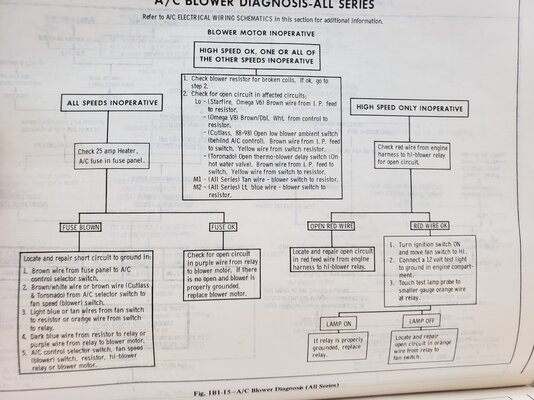

This seems to indicate that there's a problem with the "30 amp hot all the time" wire that goes to the relay, but shouldn't it still be able to work on the other 3 settings? The relay for the high setting also works, I can hear it clicking from inside the car. AC seems to work too, I can feel cool air coming out of the vents if it's on and I'm going fast enough to ram the air through.

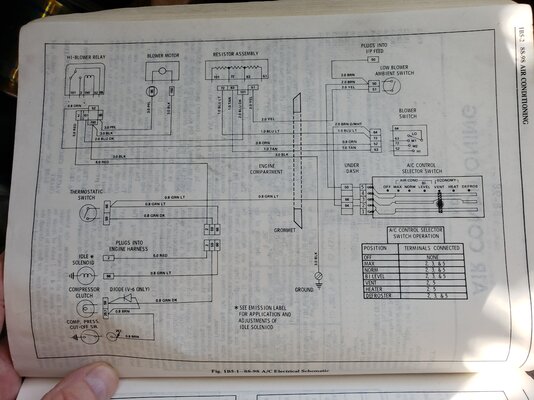

The first picture is the high blow relay (lower Shiney thing) and the blower resistor (the black thing on top with the white screw). The black blower ground wire connects to the relay connector at the same place the black circuit 150 system ground connects.

That big funky looking green wire in my pictures is how I repaired the always hot, main power supply from the engine harness. 43 years of being draped across the 403 and getting jerked around during untold numbers of engine repairs was more than the original red (10 gauge) wire could tolerate. I only had 10 gauge in green and I routed it above the engine around the back side. The second picture is of the engine harness where the always hot heavy red (in your case) wire connects. If the lower speeds work but no high, that heavy wire or the relay become highly suspect. But since none of your speed settings function, make sure the blower motor works independently of the rest of the system, if it does not, the problem is in the blower motor. If it does work with the 2 jumper wires, the high speed blower relay, or the connectors and wires on it are likely to be the culprit. It appears that your control panel switches and the wiring from it are functional, plus your resistor appears to be working normally, so again, I'd be looking for a bad ground connection (which could cause all of the problems you are experiencing).

The resistor has 3 stages of resistance. The most resistance (all 3 stages) is always on low blow. 1 click up on the panel switch bypasses one of the stages of resistance and more power goes to the blower, 2 clicks up bypasses 2 stages of resistance and even more power goes to the blower, the 3rd click up however activates the hi blow relay to supply full power directly to the blower because the resistor and the panel wiring cannot handle that much amperage.

I know that sounds overly complicated, but even way back then they were trying to reduce weight and wiring harness density. They knew the only condition that needed max amperage was max high blow, so instead of making the panel wiring and switches (plus the resistor) big and heavy enough to tolerate that much amperage, they designed a system that bypassed them for max high blow. That's why you can have lower speeds function but no high, or high speed function without the lower speeds, but if nothing works, it's likely to be a blower motor (just not 3 in a row) or a ground circuit failure.

So, I'd bench test one of the blower motors. If none of them work, go buy a lottery ticket and look out for meteors, and then get a blower motor that works. If one or more work, the problem is in the power supply, and in your case it sounds like the ground side of the supply and possibly the high amperage supply wire from the engine harness and/or hi blow relay. I wish I could touch and point at the stuff I'm talking about on your car, but describing it in words is the best I can do here.

It sounds like you have a good understanding of your multimeter and a grasp of DC power, so I'm confident that you got this.

I'm going on what I know for sure to be the case on a model that is a bit older than yours, but blower resistors and relays are still commonly used on brand new cars today. I can't imagine that computer modules were controlling those systems in your car (they didn't come along until much later), that's why I believe that your car has this sort of setup.

Keep me updated please, I'd like to know what you found out.